Next: 4.2 Simulational model Up: 4. Magnetization reversal in Previous: 4. Magnetization reversal in Contents

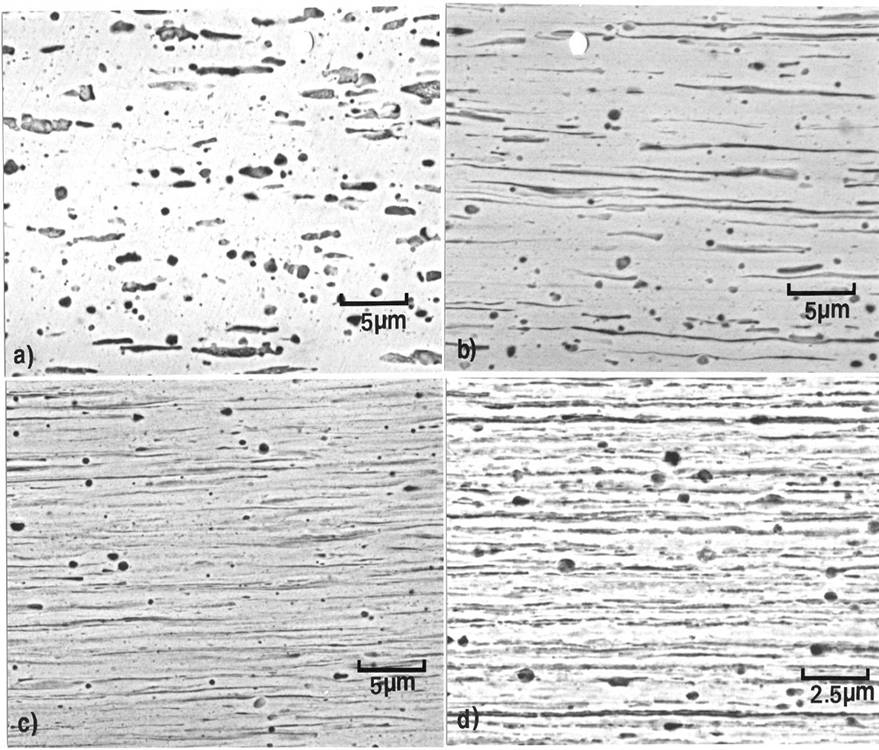

The magnetic characterization of samples has been performed by the

group of A. Hernando, J.M. González in the Instituto de

Magnetismo Aplicado (IMA). The magnetization decrease with temperature

of the nanoribbons deviated from the typical ![]() bulk behavior, as observed by P. Crespo et

al. [Crespo 04]. For small

enough cross section

dimensions this dependence becomes linear as shown in Fig. 4.2. It appears that the reduced size of

the nanoribbons modifies the dispersion relation of the magnetic

excitations (magnons). The magnons with wave length longer than the

ribbon size can not propagate. From a model describing

the magnons in the nanoribbons the value of

bulk behavior, as observed by P. Crespo et

al. [Crespo 04]. For small

enough cross section

dimensions this dependence becomes linear as shown in Fig. 4.2. It appears that the reduced size of

the nanoribbons modifies the dispersion relation of the magnetic

excitations (magnons). The magnons with wave length longer than the

ribbon size can not propagate. From a model describing

the magnons in the nanoribbons the value of ![]() was obtained as

an indirect estimate of the average particle length for the sample

in which the average cross section was

was obtained as

an indirect estimate of the average particle length for the sample

in which the average cross section was ![]() [Crespo 04].

Furthermore, the variation of the ribbon cross section modifies the

shape anisotropy resulting from its elongated shape. Due to the large

aspect ratio appearing in some samples, this anisotropy can surpass the

bcc Fe magnetocrystalline anisotropy (intrinsic parameter). Therefore,

the magnetization reversal mechanism and the coercivity will be

affected by the change of the particle dimension as observed

experimentally. The hysteresis loops were obtained by vibrating sample

magnetometer, cycling between

[Crespo 04].

Furthermore, the variation of the ribbon cross section modifies the

shape anisotropy resulting from its elongated shape. Due to the large

aspect ratio appearing in some samples, this anisotropy can surpass the

bcc Fe magnetocrystalline anisotropy (intrinsic parameter). Therefore,

the magnetization reversal mechanism and the coercivity will be

affected by the change of the particle dimension as observed

experimentally. The hysteresis loops were obtained by vibrating sample

magnetometer, cycling between ![]() and

and ![]() a magnetic field, which was applied along

the long axis of the wire-shaped samples (the cold work direction

coinciding with the Fe particles axes and the crystallographic (110)

directions). In Fig. 4.3 the

coercive field is presented as a function of the average width of the

particles.

a magnetic field, which was applied along

the long axis of the wire-shaped samples (the cold work direction

coinciding with the Fe particles axes and the crystallographic (110)

directions). In Fig. 4.3 the

coercive field is presented as a function of the average width of the

particles.

|

![\includegraphics[height=6.5cm]{Capitulo4/Graficas4/mtemperature.eps}](img641.gif)

|

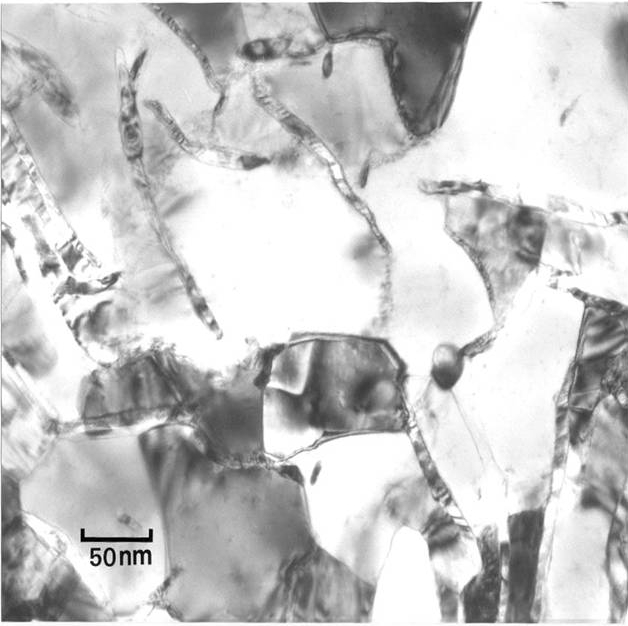

The present chapter is devoted to the micromagnetic simulations performed to analyze the magnetization reversal process taking place in those highly textured Fe nanoparticles. Our aim is to find the correspondence between experimental results and those obtained from simulations in which the local properties are systematically varied in plausible ranges. This stimulated us to attempt to go beyond traditional micromagnetics, trying to include into consideration several major contributions that are not easy to estimate, arising from the nanostructuration and fabrication process, for example residual stress or imperfect shapes, or the broken symmetry at the nanoribbon surface. In this chapter we consider, in addition to the macroscopic values of exchange, magnetization and magnetocrystalline anisotropy, different values of surface magnetocrystalline and magnetoelastic anisotropies, and the occurrence of different textures on the crystalline orientation of the nanoribbons. We also study the thermal reversal process and its possible influence on the coercivity.

![\includegraphics[height=7.cm]{Capitulo4/Graficas4/experimentalcoerc.eps}](img642.gif)

|

2008-04-04